Cupra: Racing parts from the 3D printer

NEW WAYS As soon as motorsport gets underway again, the Cupra Leon Competición, the new touring car for TCR series, is coming to the races. Some newly developed parts come from the 3D printer. The short video shows how parts Cupra Leon Competición from the 3D printer were first tested in the wind tunnel and then on the race track. For this purpose, [...]

The short video shows how Cupra Leon Competición parts from the 3D printer were first tested in the wind tunnel and then on the race track.

To this end, Cupra has teamed up with leading technology company HP. Together, the two companies have developed vehicle parts that come from the 3D printer. These are installed for the first time in the new Cupra Leon Competición, which can be used in worldwide TCR series.

Fast response time

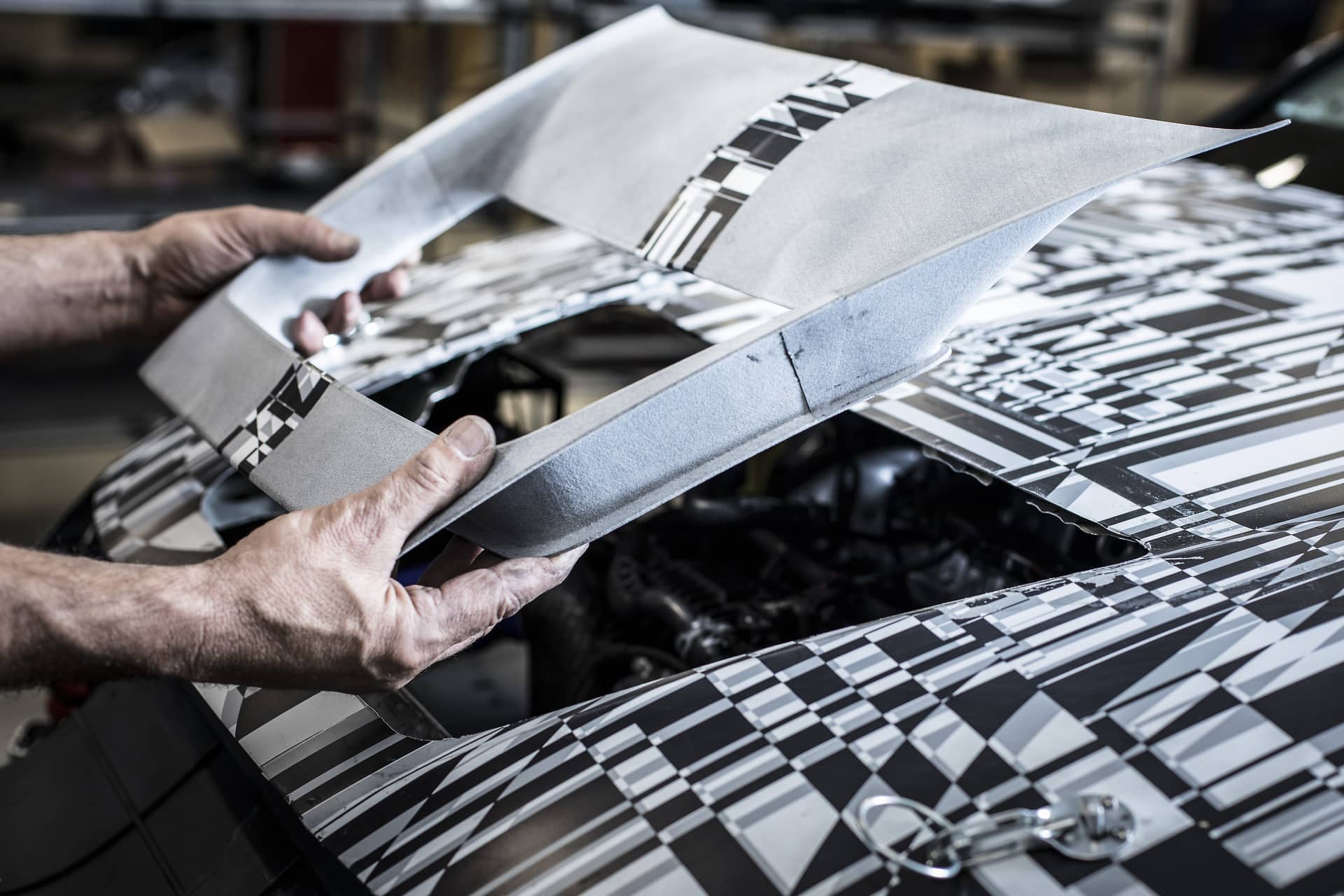

During the development of the model, the Cupra developers increasingly relied on the cooperation of 3D printers in order to be able to produce and test parts as quickly as possible. The mirrors, the control module in the steering wheel, the vents in the hood and the cooling ducts for the brakes and coolant were created in a 3D printer.

Xavi Serra, Chief Developer Cupra Racing: "We wanted to have a lot of parts in as short a time as possible, and this technology allowed us to react quickly to changes in the design. We also wanted to include an additional function to better cool the driver. So we had to create an opening in the most stressed area to achieve this."

Music of the future

According to Virginia Palacios, who is responsible for product management, 3D printing and digital production, this technology has a future.

Virginia Palacios: "3D printing technology is a game changer in the industry and speeds up development times. It also enables designers to create parts that can't be made with other technologies."

(ampnet/ww)