Porsche: Housing from the 3D printer

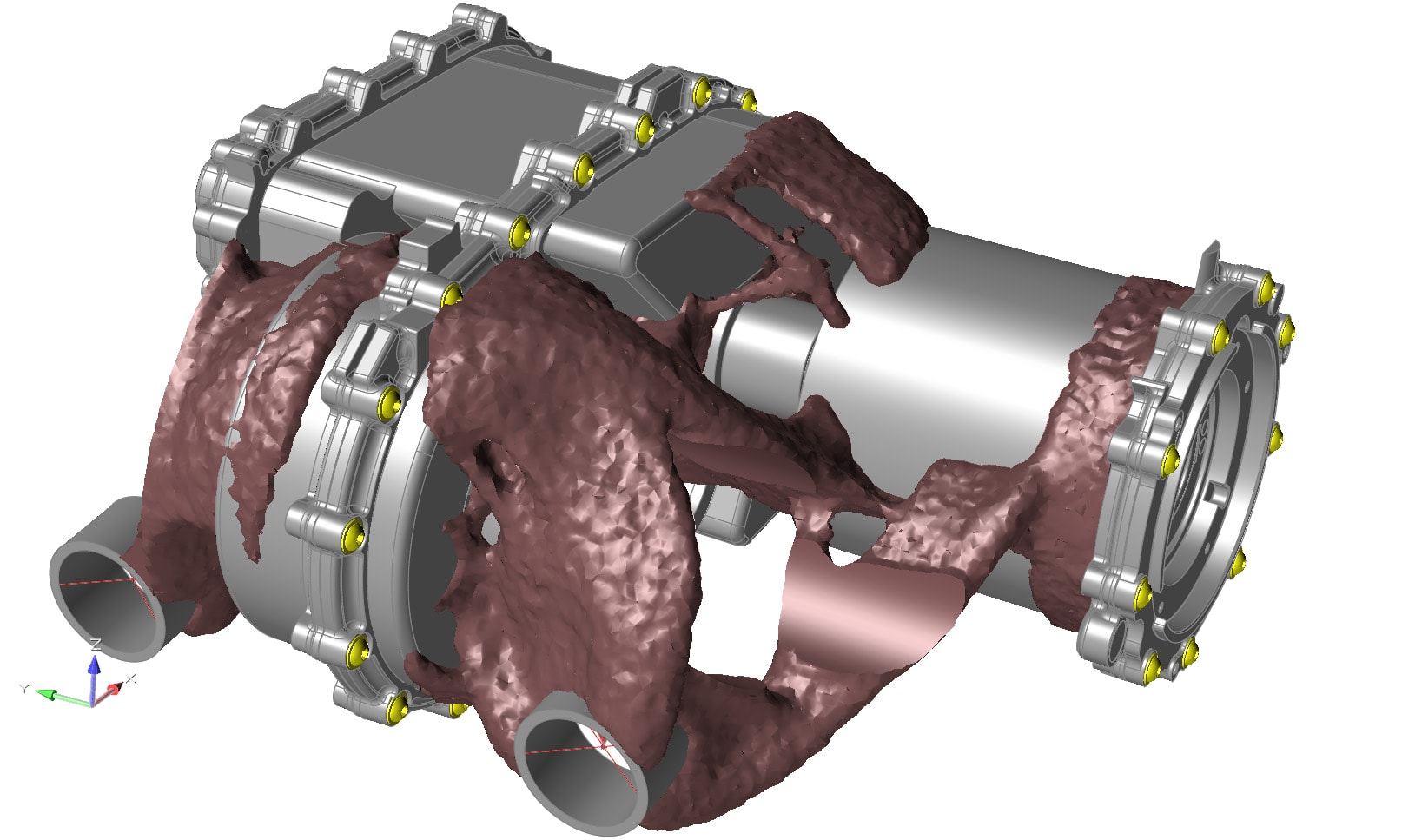

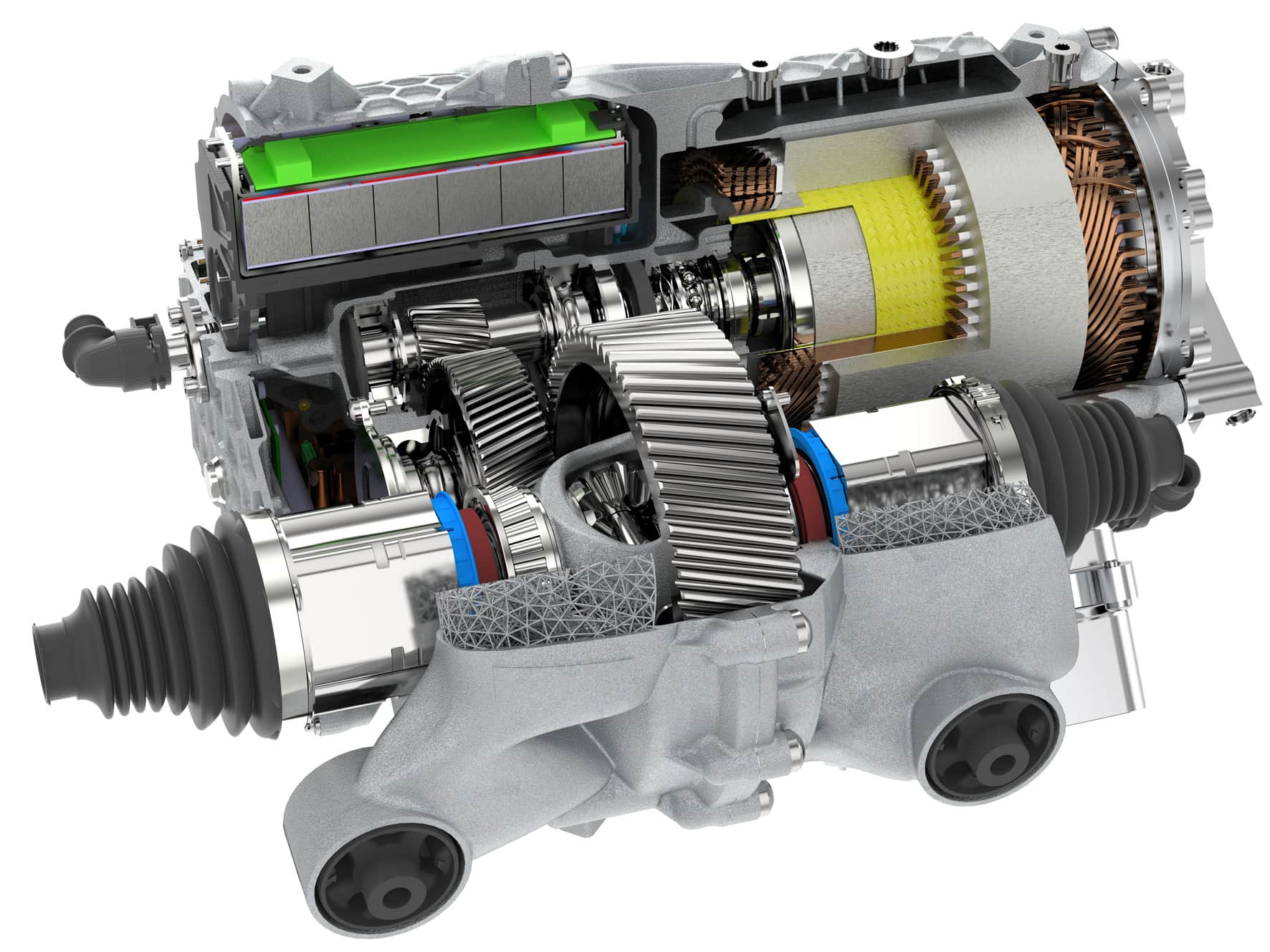

LIGHTER AND MORE COMPACT For the first time, Porsche has produced the complete housing of an electric drive using 3D printing. This drive could soon be used in a small-series sports car. 3-D printing is becoming increasingly popular in automotive engineering because it allows rapid production of prototype and series components and does not involve any sacrifices in terms of strength and weight. [...]

3D printing is becoming increasingly popular in automotive engineering because it allows rapid production of prototype and series components without sacrificing strength and weight.

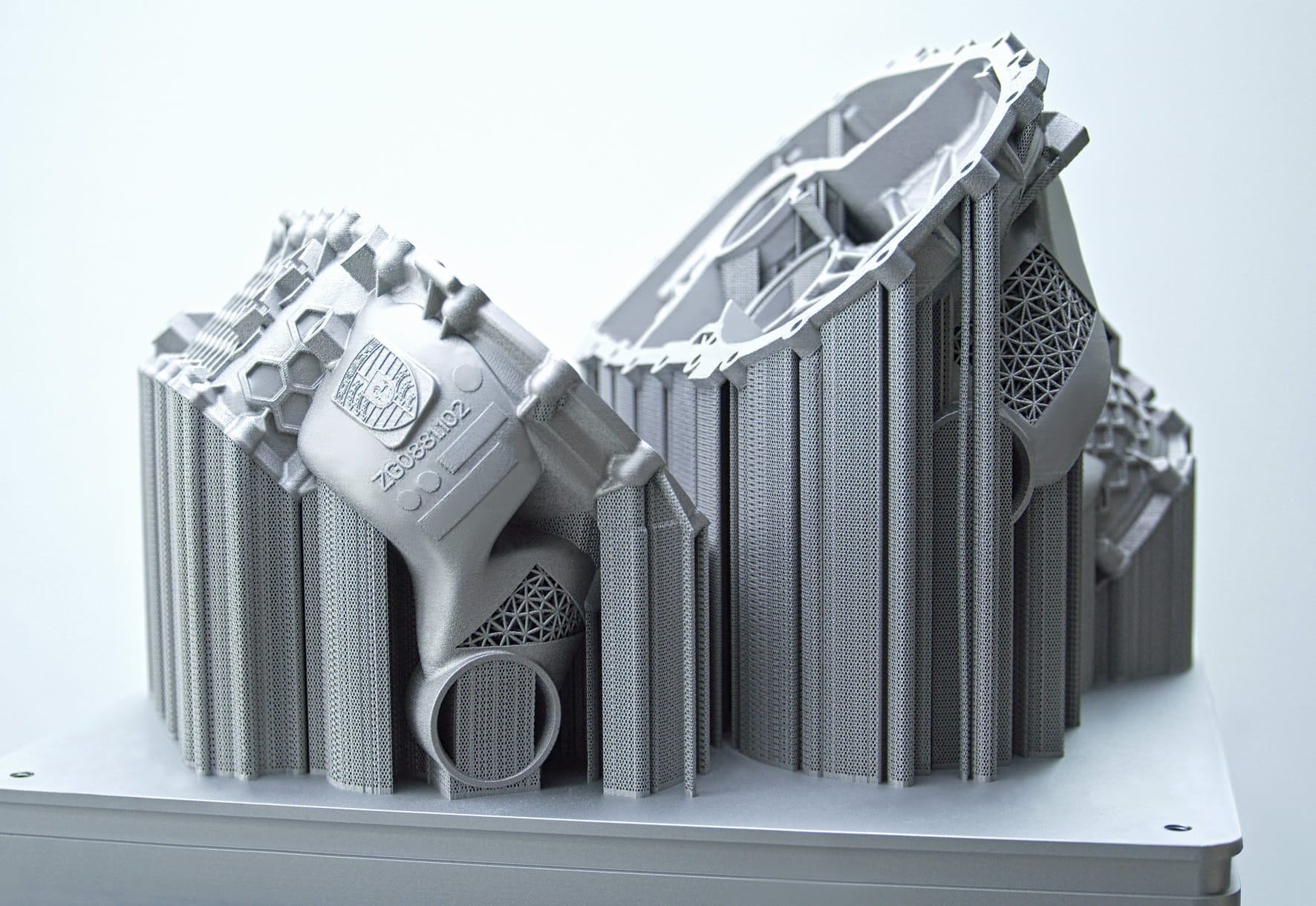

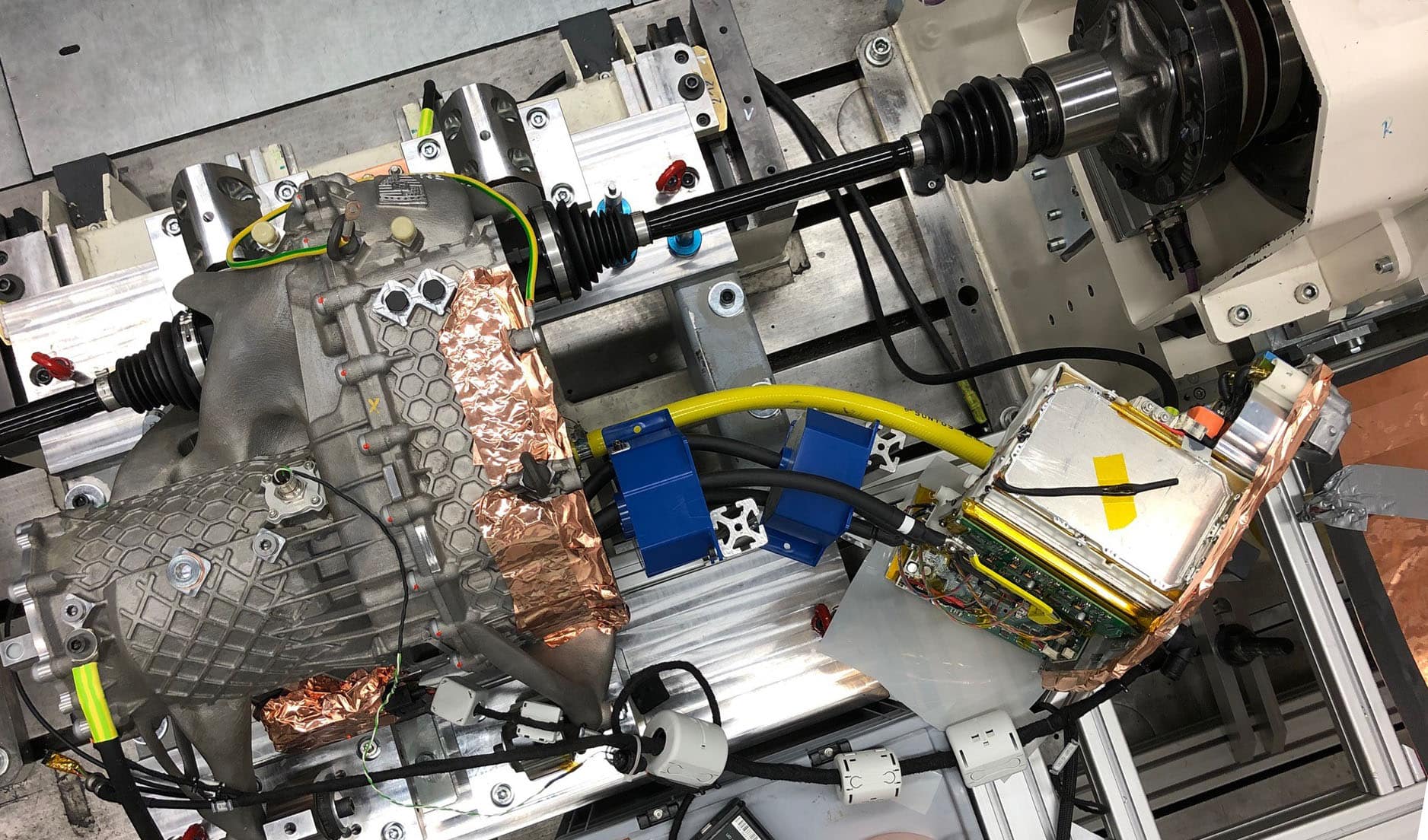

Porsche's motor-transmission unit, which was manufactured using the additive laser melting process, passed all quality and load tests without any problems. It is conceivable that the optimized electric drive could be used in a super sports car, for example.

Special structures through 3D printing

With the prototype, the engineers in predevelopment achieved several development steps in one fell swoop. The lightweight metal housing weighs less than a conventionally cast component and reduces the overall weight of the drive by around ten percent.

Special structures, which are only possible with 3D printing, significantly increased the stiffness in heavily loaded areas. Another advantage of additive manufacturing is that numerous functions and components can be integrated.

This significantly reduces the assembly effort and has advantages for the quality of the components. These are produced layer by layer from a powdered aluminum alloy. This makes designs with almost any geometry possible. Each layer is fused in itself and with the previous one.

Use on the front axle of a sports car

Furthermore, 3D printing opens up new possibilities in the development and production of low-volume components. The downstream two-stage gearbox is integrated in the same housing as the electric motor.

This highly integrated approach is designed for use on the front axle of a sports car. A few months ago, the Zuffenhausen-based company already began producing printed pistons for the engine of the 911 GT2 RS.